NEW STEEL AND SCALES ACE GRUELING WINTER CAMP TESTS.

ESEE Knives started 2020 out with a new steel for its offerings, along with one new model and revamps of its classic ESEE-3 and ESEE-4 models. This company’s been busy!

Classic Revamps

ESEE Knives now offers its classic ESEE-3 and ESEE-4 knives in S35VN steel with regular Micarta handle scales and contoured 3D G10 handles. Often referred to as a “super-steel,” S35VN is a martensitic stainless steel designed to offer improved toughness over S30V. It’s also easier to machine and polish than S30V. According to Crucible Industries LLC, its chemistry has been rebalanced so that it forms some niobium carbides, along with vanadium and chromium carbides. As an added benefit, the S35VN models fit all the standard ESEE-3 and ESEE-4 sheaths. These are often regarded as the flagship knives offered by ESEE Knives, so good just got better.

There’s a handful of survival community practitioners and experts who swear they’ve used the original 1095 carbon steel ESEE-3 (or its RAT-3 predecessor) as their go-to knife and cut their teeth with it coming up. I have to include myself in that list of practitioners. It was my “class knife” after completing the Randall’s Adventure & Training Jungle Survival Class in 2007. Since then, I’ve used it on countless trips and survival classes. It was never a “safe queen,” nor will it ever be. I still take it out on trips and know it’ll last a lifetime!

“At the end of all the slashing, puncturing, slicing and dicing, I shaved hair off my arm as an extra test. Result? There were no problems, even after the array of materials that had been cut. That’s S35VN steel performance!”

Extreme Evaluation

In the latter part of 2020, I got my mitts on both the ESEE-3 S35VN and the ESEE-4 S35VN, which featured 3D G10 scales. Taking them right out of the package, I saw a noticeable difference between the standard canvas Micarta scales and the luxury 3D G10 scales.

However, feeling them is believing! The blade finish is called “Stone Wash,” and it’s appropriately named. The texture is smooth but has a grainier look than a plain satin finish.

ESEE-4 S35VN

I wasted no time with the selection process to choose which of these knives would be my woods test subject and which would get the utility, EDC treatment.

I decided that the new 3D G10-handled ESEE-4 would be my choice for woods work, and the ESEE-3 S35VN would be on EDC detail. The weather report called for below-freezing conditions and snow. So, I packed the ESEE-4 S35VN with my cold weather gear, and away we went.

“ESEE Knives now offers its classic ESEE-3 and ESEE-4 knives in S35VN steel with regular Micarta handle scales and contoured 3D G10 handles.”

When I arrived at my camp, I found a piece of oak from a previous campfire that still had some ice on it. Rather than dig out my tomahawk to split it, I opted to use the ESEE-4 S35VN.

hammering the exposed tang with a heavy baton. He repeated this test quite a few times. (Photo: Reuben Bolieu)

I proceeded to split the chunky oak with the ESEE-4—tip down, held in an icepick grip and a stout baton in hand. I had a large, heavy baton in my camp that I’d cut from a piece of hard maple. It was cut with a saw at the junction of a Y section, so there was a handle of sorts, offering a lot of leverage when splitting or pounding stakes into the hard ground.

However, I wanted a more traditional baton mallet. Out came the bow saw, which I used to cut around the circumference of the log that would act as my stop-cut. The log was put on a stump, and I used the ESEE-4 S35VN to baton and split sections, forming a rough handle. Eventually, the knife was used to shave down and fine-tune the handle (which I plan on using for many years).

“Often referred to as a ‘super-steel,’ S35VN is a martensitic stainless steel designed to offer improved toughness over S30V.”

Wanting to get my fire started, I needed kindling. I planned to use the ESEE-4 S35VN for as many tasks as possible. Using a bow saw, I cut a few lengths of maple about the size of my small wood stove. Once I stood the wood on end, I put the knife edge in the middle of the wood. I simply whacked the spine of the knife, and it powered through, splitting the wood. This made for very dry, uniform, finger-thickness pieces of fuel.

The trick to this is to not beat the knife all the way down into the support stump; rather, you need to get it a little more than halfway down the length of the wood and use a twist of the wrist to split the wood apart. This works well and, unless there’s a knot, it isn’t hard on the knife’s edge. Well, there were knots. Avoiding these when using a knife or axe is like digging in the dirt and trying not to hit any rocks with your shovel!

“This is a knife steel brought in to answer the requests of the customers who asked for it.”

At the end of day one, I closely examined the blade while I was about to prepare the kindling and tinder for the next morning’s fire. The blade had a few chips in the belly area. I wasn’t surprised, because I know this type of steel is not made for these tasks. Sure, it can get the job done, but at a price. So, I used a Smith’s fine diamond sharpening stone I keep in the camp, along with a strop that had been provided by my friends at Powers Carvings & Crafts. I was skeptical that the fine diamond stone would actually do the trick, but it was enough to take care of the chipped area.

A couple of days later—and to my surprise—the knife chipped again in the same area after strenuous woods use. Again, it wasn’t a “deal-breaker,” because this knife version was never intended for this type of use. In fact, ESEE Knives wants its customers to recognize this and puts an advisory on its website: “Our stainless knives are warranted just like our carbon steel knives. However, we advise that because they are hardened to a higher Rockwell hardness than our carbon steel knives, they are easier to break if you pry with them.”

“After many weeks with the ESEE S35VN 3D-handled knives, I learned that S35VN isn’t hard to sharpen; it’s just a very hard, wear-resistant steel and will take a longer amount of time

to touch up.”

After retouching the edge on the strop, I made a figure-4 deadfall trap. Using a heavy chopping tool, I procured a broomstick-thick piece of green witch hazel for my trap parts; its smaller branches were used for utensils and camp crafts. The trap involved cross-grain batoning with the ESEE-4 S35VN to make two right angles on the diagonal end and the upright vertical pieces. Four more L7-type notches were made, and all it took was a little trick at the end to speed up the trap. This was more about the handle comfort and choking up on the blade via the choil at the base of the blade. (Being accustomed to the classic ESEE series knives, I remember the feel of the flat scales. The new 3D G10 scales were built for comfort!)

Someone had left a metal ammo canister from a geocache near my camp. I used it to test the blade further. I put on some leather work gloves and stabbed the ESEE-4 S35VN knife into the canister as hard as I could and then used the mallet to pound it in some more. I made sure to rock the blade back and forth a fair amount before pulling it out—for good measure, of course. The blade had a couple of chips, but there was no damage to the tip or scratches. It just chipped a little, as they all do. (Every carbon steel blade I’ve done this with has also chipped.)

“Avoiding [knots] when using a knife or axe is like digging in the dirt and trying not to hit any rocks with your shovel.”

Next, I prepped veggies with the ESEE-4 S35VN without any touch-ups. It sliced—not wedge-split—carrots and celery as thick blades often do. Stew was on the way, and the knife also served as the stew’s stirring utensil. I finished out the food portion of the evaluation by making a simple handle for my camp frying pan. I cross-grain batoned both ends of the leftover witch hazel and tapered one end to get a good fit. After that, I called it a day.

ESEE-4 S35VN FIXED BLADE KNIFE

- Overall length: 9.0 inches

- Cutting edge length: 4.1 inches

- Overall blade length: 4.5 inches

- Maximum thickness: 0.188 inch

- Steel: S35VN; 59-60 Rc

- Weight (knife only): 8.0 ounces

- Removable Handles: Canvas Micarta, G10, 3D G10

- Sheath: Molded with clip plate

- Made in the U.S.A.

MSRP: $213

ESEE-3 S35VN

The original model is the one that started it all. It was called the RAT-3 (for RAT Cutlery) before the company became ESEE Knives. As I’ve already mentioned, I was fortunate enough to get one back in 2007, and it’s still going strong today.

The original 1095 carbon steel version is still available and now can be had with the new 3D G10 scales. However, the luxury model is the ESEE-3 S35VN, released in early 2020. This version has black G10 scales and a noticeable difference in the feel of the handle: It’s comfortable!

Besides the handle and blade finishes being obviously different in appearance from the classic ESEE-3, the steel on the 3D model also performs differently. Is it better? No; it’s different. But it might be better for those who know what to expect from this exotic steel. This is a knife steel brought in to answer the requests of the customers who asked for it. Most likely, those customers will expect the S35VN steel to hold an edge longer and keep at bay corrosion and staining from blood, food and the elements. After all, that’s what this steel excels at!

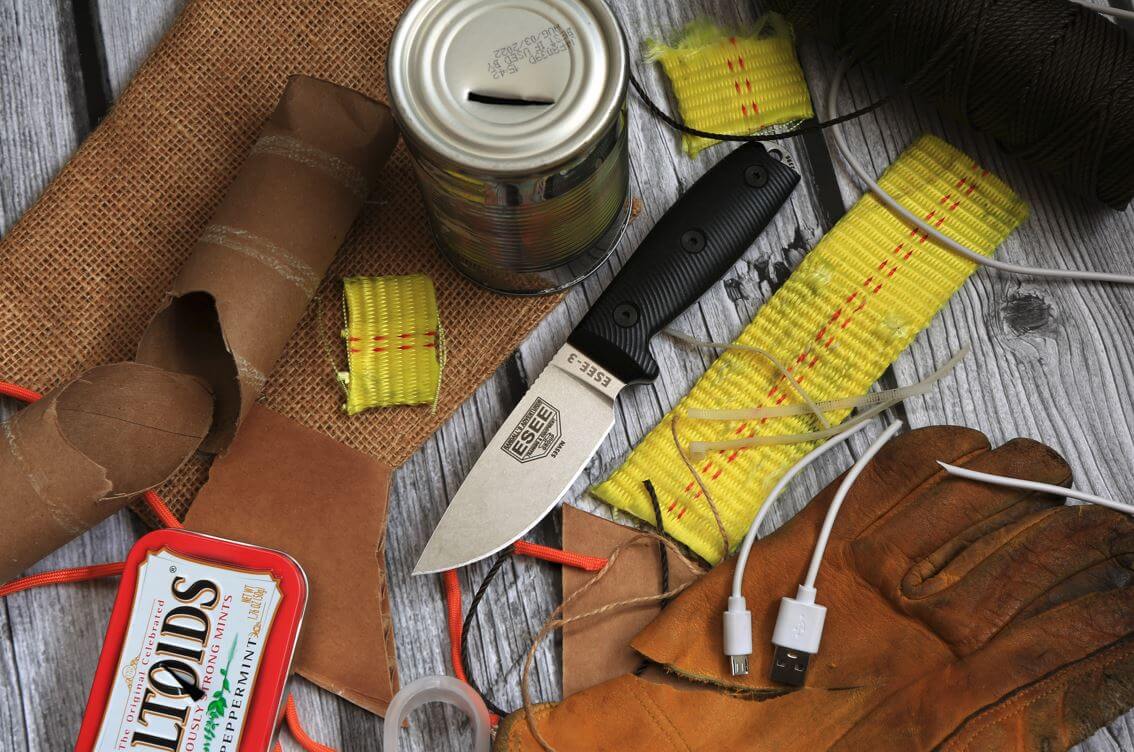

I first used the ESEE-3 S35VN on some 10,000-pound tow strapping, securely holding one end of the knife and slicing through a few times using different parts of the blade. There was no drag, no hesitation. Then, I placed the tow strap on a cutting board and sliced it as I would peppers for a stir fry; this was no problem either.

From that point on, it was a “slasher fest.” Nothing was sacred! Cardboard was next, because it’s quite abrasive on cutting edges and could hamper the results of the materials I’d be testing later. Paracord, jute twine, bank line and zip-ties came after that—all without a hitch. I’d recently retired an old pair of cowhide leather gloves and gave them a single slash—cleanly through. I cut through the plastic holder of a watch and then a length of USB cord for a phone. Then, I moved on to the “hard stuff.”

I stabbed into an Altoids Mints tin and then deeply into a tin can to simulate using the knife as a can opener. The aftermath: two small chips— one from the Altoids tin and the other from the tin can. This was nothing to cry about.

However, the true test was next!

After working with all the fibrous materials, it was time to see how the edge had suffered, degraded or lost any keenness. Tomatoes, carrots, peppers and celery were about to “spill the beans” for this test. The ESEE-3 S35VN sliced as if it were new and right out of the box, and the belly and thin edge only complemented the S35VN’s inherent attributes.

At the end of all the slashing, puncturing, slicing and dicing, I shaved hair off my arm as an extra test. The result? There were no problems, even after the array of materials that had been cut. That’s S35VN steel performance!

After many weeks with the ESEE S35VN 3D-handled knives, I learned that S35VN isn’t hard to sharpen; it’s just a very hard, wear-resistant steel and will take a longer amount of time to touch up. I also learned that the steel isn’t great for woods use unless it’s being used for skinning or meal preps.

Nevertheless, where it falls short for one person’s needs, it shines for others—just as any piece of gear does. I’m sure we’ll see more ESEE models manufactured with this steel in the future.

One again, it was a privilege to be part of the ESEE-3 and ESEE-4 testing legacy—14 years and counting!

ESEE-3 S35VN FIXED BLADE KNIFE

- Overall length: 8.19 inches

- Cutting edge length: 3.38 inches

- Overall blade length: 3.88 inches

- Maximum thickness: 0.125 inch

- Steel: S35VN; 59-60 Rc

- Weight: 6 ounces (knife only)

- Weight: 9 ounces (knife and sheath)

- Sheath: Molded

- Finish: Stone Wash

- Handle: 3D G10

- Made in the U.S.A.

MSRP: $205

New 3D-Contoured Scales

While this isn’t the first time ESEE has used G10 for its scale materials, it’s the more comfortable choice. Previously, only flat, orange scales have been offered for various models. The combination of S35VN with 3D G10 scales marks major additions to ESEE Knives.

Now, the ESEE-4 joins the lineup, along with the ESEE-3 and newish design: the Xancudo fixed blade. All feature S35VN with 3D G10 scales. The 3D G10 contoured scales feature a curving palm swell and an appropriate deep finger groove beneath the guard. Currently, the 3D G10 scales are available for the ESEE-5 and ESEE-6 as well, but only for carbon steel versions.

However, keep an eye out to see what other ESEE designs get this new luxury overhaul of S35VN with 3D G10 scales!

G10

G10 is extremely popular in the knife and gun industries because it’s most commonly used for knife handles and gun grips. Prior to that, it proved its toughness and durability in challenging electrical and mechanical device applications.

Built from durable fiberglass and epoxy resin and then formed under high temperature and pressure, G10 is unlike other polymers: It won’t melt. G10 is also resistant to the effects of temperature and is extremely lightweight. It’s a rugged, resilient, reliable material suitable for a variety of uses, including aesthetic effects. While G10 is similar to other materials such as Micarta and carbon fiber, the primary difference is that G10 uses glass fibers. Simply put: G10 offers brilliant colors, extreme toughness, durability and chemical resistance.

SOURCES

ESEE Knives

(256) 613-0372

ESEEKnives.com

Powers Carvings & Crafts

Etsy.com/shop/PowersCarvingsCrafts

Smith’s Products

SmithsProducts.com

Editor’s note: A version of this article first appeared in the June, 2021 print issue of American Survival Guide.